In the trucking and transportation industry, Driver Vehicle Inspection Reports (DVIRs) are important for both safety and compliance. These reports aren’t just more red tape; they’re integral to ensuring that each vehicle is roadworthy and meets all safety standards. The traditional method of filling out DVIR forms on paper has been the norm for years. But, like many things around us, it’s increasingly showing its age when everything is going digital.

Electronic DVIR forms offer a modern solution that addresses many of these pain points. They promise greater accuracy, easy storage and retrieval, and overall improved efficiency. Today, we’re taking a comprehensive look at the advantages of electronic DVIR forms, the key components that an effective electronic DVIR should include, and practical steps for making the transition from paper to digital. Whether you’re a driver or a delivery manager, this guide has the knowledge you need to modernize your DVIR process effectively.

Importance of DVIRs in Trucking and Transportation

DVIRs are a critical safety measure in the transportation business. Think of DVIRs as the first line of defense against potential vehicle malfunctions that could lead to accidents or breakdowns. Before a vehicle hits the road, a DVIR ensures that it’s in optimal condition, from the brakes and lights to the tires and engine. This proactive approach to vehicle maintenance can save lives, prevent costly breakdowns, and even improve fuel efficiency.

The Federal Motor Carrier Safety Administration (FMCSA) takes DVIRs very seriously. According to their regulations, failure to complete a DVIR or knowingly operating a vehicle without resolving the defects identified can result in substantial fines and penalties. In some cases, the penalties can go as high as $1,270 per violation per day.

Avoiding fines isn’t the important thing. Properly conducted DVIRs promote safety within your organization. They instill a sense of responsibility among drivers, who are the first to notice and report issues. Proactive reporting can lead to timely repairs, reducing the risk of catastrophic failures that could endanger lives and result in expensive legal battles. A study by the National Highway Traffic Safety Administration found that vehicle-related factors contributed to 2% of all trucking accidents, a figure that could potentially be reduced with rigorous DVIR protocols.

DVIRs can also have a direct impact on a company’s bottom line. Preventive maintenance, facilitated by thorough inspections, can extend the lifespan of a vehicle. This means fewer new vehicle purchases in the long run and greater savings.

The Limitations of Paper DVIR Forms

Issues with Data Accuracy, Storage, and Retrieval

- Human Error: One of the most glaring issues with paper DVIR forms is human error. When drivers are manually filling out these forms, there’s always the risk of miscalculations or overlooked details, and that can have serious repercussions for compliance and safety.

- Illegible Handwriting: Your best driver may have poor penmanship, leading to mistakes or incorrect data interpretation. This makes audits or inspections even more challenging.

- Storage Challenges: Paper forms can be lost or damaged. Whether it’s due to water damage, fire, or simple wear and tear, once a form is compromised, the data on it is often gone. This poses a significant risk, especially when these forms are crucial for regulatory compliance.

- Data Inconsistency: With multiple drivers filling out forms in varying styles and terminologies, maintaining a consistent data set becomes a logistical challenge. Inconsistency can create hurdles when it comes to data analysis or report generation.

A study by TruckInfo underscored the gravity of these issues, revealing that up to 20% of paper logs contain errors that can lead to compliance issues and fines.

Challenges and Drawbacks

- Storage: The physical space required to store these forms can become a burden for companies, especially those with limited office space. As these forms accumulate over time, the task of organizing and storing them becomes increasingly cumbersome.

- Retrieval: When it’s time to retrieve old records for audits or inspections, the process can be incredibly time-consuming.

- Lost Time: The time drivers and staff spend on manual processes related to paper DVIRs is time taken away from your company.

- Environmental Concerns: The use of paper contributes to deforestation and waste, making the shift to electronic forms an eco-friendly choice.

- Inconvenience: Paper forms lack the convenience of quick sharing or real-time updates. In situations where immediate access to a DVIR is required, the limitations of a paper-based system become glaringly obvious.

The limitations of paper DVIR forms are many, affecting everything from data accuracy to operational efficiency. The move to electronic DVIR forms offers a way to mitigate these issues, providing a more reliable and efficient alternative.

Advantages of Electronic DVIR Forms

How They Work and Their Features

Electronic DVIR forms are a game-changer in the transportation industry. Unlike their paper counterparts, these digital forms can be accessed and filled out using a tablet or smartphone. This level of accessibility means that drivers can complete their inspection reports from anywhere, whether they’re in the cab of their truck or outside inspecting the vehicle.

The user interface of electronic DVIRs is designed for ease of use. Features often include drop-down menus that standardize the data entry process, making it quicker and more accurate. This standardization is crucial for maintaining data consistency across multiple drivers and vehicles.

Another standout feature is the ability to attach photos directly to the form. If a driver identifies a defect or issue during the inspection, they can snap a photo with their device and attach it to the relevant section of the form. This visual evidence can be invaluable during audits or when communicating with maintenance teams.

Benefits in Terms of Efficiency

Real-time Data Entry and Transmission

One of the most significant advantages of electronic DVIR forms is real-time data entry and transmission. As soon as a driver completes an inspection, the form can be instantly updated and sent to the relevant departments. This immediacy is crucial for quick decision-making and immediate action, especially in cases where vehicle defects are identified.

Improved Accuracy and Legibility

The digital nature of electronic DVIRs eliminates the issues of illegible handwriting and manual errors, leading to more accurate and reliable data. This can be a significant factor in ensuring compliance and avoiding fines.

Reduces Administrative Work and Paperwork

Switching to electronic forms can dramatically reduce the administrative burden on your team. There’s no need to manually enter data from paper forms into a computer system, saving time, resources, and money.

Enhanced Compliance and Reporting

Electronic DVIRs come with built-in features for generating reports, making it easier to prepare for audits or internal reviews. The ability to quickly generate and share these reports contributes to a more transparent operational environment.

Key Components of an Effective Electronic DVIR

An effective electronic DVIR is a comprehensive tool designed to streamline the inspection process while ensuring the highest levels of accuracy and compliance. To achieve this, there are several key components that should be included in any electronic DVIR.

Vehicle Identification Details

The first crucial element is the vehicle identification details. This includes the make, model, and license plate number of the vehicle being inspected. Some advanced electronic DVIRs even allow for the scanning of a QR code or VIN (Vehicle Identification Number) for automatic data entry. This feature not only speeds up the process but also eliminates the possibility of manual entry errors.

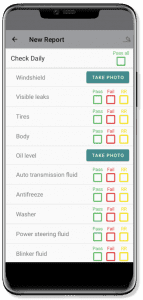

Inspection Items and Categories

A well-designed electronic DVIR should have a comprehensive list of inspection items and categories. These typically include brakes, lights, tires, engine components, and other essential systems. The list should be customizable to fit the specific needs and requirements of your fleet. Having a pre-defined list ensures that no critical inspection points are missed and allows for a standardized inspection process across all vehicles.

Defect Identification and Reporting

One of the standout features of electronic DVIRs is the ability to identify and report defects with photo attachments. If a driver notices an issue, they can take a photo and attach it to the form. This visual evidence provides a clearer understanding of the issue, making it easier for maintenance teams to prioritize and address defects. It also serves as a valuable record during audits or inspections, substantiating the written observations with photographic evidence.

Certification and Signatures

To ensure the authenticity of the inspection, electronic DVIRs often include a feature for digital signatures. Drivers can sign off on their inspections using a stylus or their finger, providing a secure and verifiable method of certification. This digital signature is timestamped, adding an additional layer of accountability and integrity to the process.

Transitioning to Electronic DVIR Forms

Steps and Considerations

Transitioning from paper to electronic DVIR forms is a strategic move that requires careful planning and execution. The first step in this transition is to evaluate your organization’s specific needs. What are the pain points with your current system? What features are most important to you in an electronic DVIR? Once you have a clear understanding of your requirements, you can begin researching and selecting a compatible electronic DVIR solution that meets those needs.

The next step is to allocate resources for system setup and integration. This involves both financial investment and manpower. You’ll need to budget for the cost of the software, any necessary hardware like tablets or smartphones, and potentially any costs associated with integrating the new system into your existing IT infrastructure.

Employee Training and Onboarding

Once the system is in place, the focus shifts to employee training and onboarding, which is important for a smooth transition. Employees need to understand not just the “how” but also the “why” behind the change. Training can take various forms, from online tutorials and webinars to in-person training sessions. The goal is to make sure everyone who will use the system feels comfortable and competent doing so.

It’s also good to have a few “super users” or champions who can become experts in the new system and assist others during the transition. These individuals can serve as go-to resources for any questions or challenges that arise.

Best Practices

Start small. Test the system with a smaller team or a single route first. This pilot phase allows you to identify any issues or areas for improvement before a full-scale rollout.

Keep lines of communication open for feedback from all users, including drivers and administrative staff. This feedback is crucial for fine-tuning the system and addressing any challenges that may arise.

Transitioning to electronic DVIR forms is a significant but manageable task. When done correctly, it can yield substantial benefits in terms of efficiency, accuracy, and compliance.

EXTRA DVIR: A Compatible and Robust Solution

Elite EXTRA provides a comprehensive electronic DVIR solution that seamlessly integrates with route optimization software. This compatibility is particularly beneficial for organizations looking to streamline their entire logistics and transportation workflow, not just the vehicle inspection process.

Compatibility with Route Optimization Software

One of the standout features of Elite EXTRA’s DVIR solution is its compatibility with route optimization software. This means you can plan the most efficient routes while ensuring that all vehicles are in optimal condition, all within the same system. This level of integration can significantly enhance operational efficiency by reducing the time spent toggling between different platforms.

User-Friendly Interface

Elite EXTRA’s electronic DVIR is designed with a user-friendly interface that makes it easy for drivers to complete their inspections quickly and accurately. Features like drop-down menus and photo attachments are included, aligning with the key components of an effective electronic DVIR discussed earlier.

Scalability

As your fleet grows, you need a DVIR solution that can grow with you. Elite EXTRA’s system is fully scalable, allowing for easy addition of new vehicles and routes. This scalability ensures that the system remains a long-term solution, capable of adapting to your evolving needs.

Security and Compliance

Compliance is non-negotiable and the security features of Elite EXTRA’s DVIR solution include secure digital signatures and timestamp features, ensuring the authenticity and integrity of each inspection report.

The Imperative Shift to Electronic DVIR Forms

Switching to electronic DVIR forms is a substantial operational upgrade that modern trucking and transportation companies can’t afford to overlook. From efficiency gains and streamlined administrative processes to enhanced compliance and real-time data management, the advantages are worth the investment.

The transition to electronic DVIRs is about embracing a smarter, more efficient way of doing business. It’s about equipping your drivers with the tools they need to perform their jobs more effectively and providing your administrative team with the resources to manage fleet operations more efficiently.

In today’s competitive market, where margins are thin and customer expectations are high, operational efficiency is required. Electronic DVIRs offer a pathway to achieving this efficiency, providing a robust and reliable system for vehicle inspections that integrates seamlessly with other aspects of fleet management.

If you’re ready to make this pivotal transition, Elite EXTRA is here to help! Contact us to get started with electronic DVIRs and improve your deliveries.

Sources

https://www.fmcsa.dot.gov /taxonomy/term/11541

https://www.nhtsa.gov/

https://www.truckinfo.net /trucking/stats.htm

https://www.fleetequipmentmag.com /fleets-gathering-better-asset-management/

https://www.trucksafe.com /post/understanding-the-driver-vehicle-inspection-report-dvir-process