A significant portion of the burden of customer satisfaction is placed on efficient delivery services, and both B2B and B2C consumers have very high expectations. Sixty-two percent of shoppers expect orders to arrive in less than 3 business days, and 56% of abandoned carts are related to delivery concerns. Yet, cheap and speedy delivery can be difficult to achieve when fuel costs keep rising. The price of regular gas rose 49% and the price of diesel fuel rose 55% from January to June 2022. Although variation in fuel prices aren’t always that dramatic, it is hard to predict. To meet customer demand and keep prices low, businesses will need to find ways to improve fuel consumption. Modern technology provides the answer in the form of a fuel management system.

A modern fuel management system is designed to address many of the pain points in fleet management to help delivery companies monitor fuel usage and avoid waste. In this blog, we’ll explore the challenges of traditional fuel management and the ways technology can help delivery companies manage fuel use.

Understanding the Challenges of Traditional Fuel Management

Labor and fuel costs are the two biggest price drivers in the delivery industry. These costs are especially predominant in last-mile delivery. As prices and consumer expectations rise simultaneously, delivery companies must seek ways to overcome circumstances beyond their control. In other words, they have to find ways to reduce fuel costs without impacting customer satisfaction. The best way to achieve this is through the management of fuel consumption.

To monitor and control fuel usage, companies must get a clear understanding of where fuel is lost. Unfortunately, a variety of factors contribute to excess fuel use, and many of them are difficult to detect. What appears to be fuel consumption may be waste due to fuel theft, fraud, poor route mapping, logistics mistakes, or poor driving habits. Without clear data or modern processes, accurately diagnosing issues associated with fuel usage has long been a challenge in the shipping industry.

Limitations of Manual Fuel Tracking Methods

Manually tracking fuel use requires drivers to monitor miles traveled and keep fuel receipts. The process is prone to error because of the complexity involved and the wide margins for error. The biggest limitations of manual fuel tracking include:

- Inaccurate data recording and reporting: Manual data reporting requires the use of hard copies of receipts and human input. Lost receipts or incorrect entries can leave companies working with inaccurate data.

- Time-consuming manual processes: Comparing fuel receipts and mileage typically requires the use of complex spreadsheets and manual data entry. These processes can slow down delivery processes and impact delivery times.

- Increased risk of errors and fraud: When information changes hands many times, incorrect entries can occur at any time during the data chain. Furthermore, fraud like unauthorized purchases or card sharing can’t be detected through manual processes.

Lack of Real-Time Visibility and Control Over Fuel Usage

Only a few decades ago, delivery drivers had minimal communication with dispatch while on the road. A route was mapped before the trip, and communication was reestablished upon product delivery. Even with modern phones, companies have minimal visibility into bottlenecks during shipping and delivery processes. Therefore, the reasons for excess fuel use remain difficult to pinpoint.

Inefficient Data Analysis and Decision Making

Lack of visibility and outdated data collection methods make it challenging for delivery managers to oversee driver performance. Without accurate data surrounding the details of delivery, minimal information is available about fuel use. As a result, benchmarks and KPIs are more likely to be unreliable. With skewed data, company leaders and fleet managers don’t have the knowledge they need to make informed decisions about fuel management and practices to reduce excess fuel consumption.

The Role of Technology in Fuel Management Systems

Without technology, addressing the issues in fleet fuel management would be difficult, if not impossible. However, modern technology can play a valuable role in providing necessary data to improve fuel consumption. High-quality software solutions offer new ways to collect data, so fleet managers can analyze changes in fuel consumption and address many of the challenges that have long plagued the shipping industry.

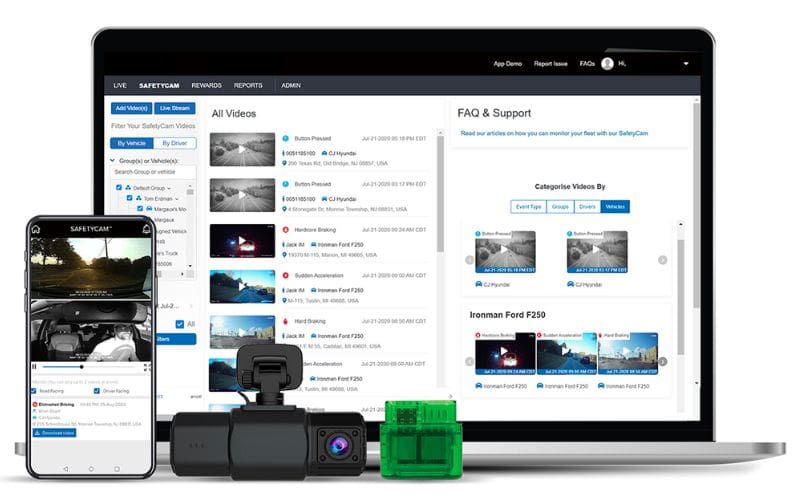

A fuel management system is a category of fleet management that uses telematics and analytical software to record fuel consumption data and improve fuel economy. With the use of highly sensitive equipment and sensors, systems can accurately monitor fuel use and provide real-time updates regarding travel conditions and unexpected fuel loss.

Key Technologies Shaping Fuel Management

In the past, fuel reporting was comprised of manual entries in fuel logs that described the date and time of the transaction, price per gallon of fuel, number of gallons purchased, and odometer data at the time of the transaction. This information provided limited insight into changes in fuel consumption.

Modern technologies use a variety of tools to give fleet managers insight into the specific incidents that make up a delivery. Key technologies shaping fuel management include:

- Automated fuel tracking and data collection: Fuel management systems automatically collect data about fuel input and usage, eliminating errors related to manual entry. These systems can recognize red flags like over-fueling, fueling at unapproved vendors, sharply decreasing fuel levels, and fueling outside geofencing perimeters.

- Telematics and GPS integration: Telematics uses onboard diagnostics to monitor and report on details like speed, idling, fuel use, low tire pressure, and more. When integrated with GPS, fleet managers can track vehicles in real time.

- Mobile applications for real-time monitoring: App-based tracking uses an app downloaded to a mobile phone to track delivery drivers’ movements in real time. Mobile apps can be used throughout an entire trip to measure fuel usage and driver performance.

- Cloud-based platforms for data storage and analysis: Sensors can be integrated into fuel systems, GPS devices, odometers, etc. to automatically collect all data from machines rather than drivers. The data can be uploaded instantly to cloud-based platforms for storage and analysis.

Benefits of Technology-Driven Fuel Management Systems

Efficient fuel consumption depends on many factors for a single vehicle. When you’re responsible for managing the fuel use of an entire fleet, manual processes don’t have much to offer. Technology-driven fuel management systems use several types of equipment to address the issues plaguing the shipping and delivery industry for decades. Investing in a modern fuel management system offers these essential benefits.

Improved Accuracy and Reliability of Fuel Data

Fuel management systems use onboard sensors to automatically collect the data required for fuel reporting. Drivers no longer have to take the time to enter the data manually or save receipts. As a result, errors are eliminated. Collected data is automatically categorized and stored in easily accessible cloud-based platforms for further analysis as needed.

Enhanced Efficiency and Time Savings

Fuel management systems eliminate reporting requirements for drivers, but the value of the software isn’t limited to vehicles. Automated reporting eliminates the need for complex spreadsheets and manual data entry in the back office. Furthermore, when the system is integrated with the vehicle’s GPS, it can automatically calculate traveled distance and purchased fuel for IFTA tax reports. Eliminating data entry at multiple points offers significant time savings and fewer opportunities for error.

Real-Time Visibility and Control Over Fuel Usage

To reduce fuel costs, companies need a clear understanding of fuel usage. It would seem that two trucks traveling the same distance on the same day would have equal fuel consumption. Yet this is rarely the case. Up to 30% of a vehicle’s fuel efficiency is impacted by driver behavior.

Fuel management systems use GPS and telematics to gather real-time data on how fuel is consumed during different parts of the shipping journey. The data can be analyzed to provide insight into driver behavior, road conditions, and other factors that can affect fuel consumption. With real-time tracking, fleet managers can gain insight into how different driver behaviors affect fuel consumption. Telematics detect driver behaviors like speeding, excessive idling, and harsh acceleration that play a role in reducing fuel economy. The information can then be used to advise and train drivers participating in such behavior.

Data-Driven Insights for Informed Decision-Making

Fuel reporting isn’t just busy work for drivers or information for tax purposes. Fleet managers continually collect data regarding fuel management with the goal of improving systems and cutting costs. Technology-driven fuel management systems automatically collect precise data that can be used to uncover insights into when and why fuel use increases. The information can then be used to determine if there are ways to decrease fuel use. For example, investments in routine vehicle maintenance and upgraded systems can help vehicles burn fuel more efficiently.

Reduction in Fuel Theft and Unauthorized Usage

As fuel prices constantly increase, theft and unauthorized fueling are common concerns. Eighty-six percent of US fleet managers think some of their drivers are committing fraudulent activity. Yet, this activity doesn’t account for all fraud. Fuel fraud is committed by drivers and external attackers. In either case, fuel funds are used in a discreet manner that appears as a routine purchase. Location tracking and telematics combine to recognize internal actions like personal purchases, and external attacks like skimming. The ability to identify fraud is the first step in preventing it.

Fuel theft is also a major concern for all drivers. Skyrocketing gas prices have prompted thieves to steal millions of dollars worth of fuel from gas stations, freight trucks, and even personal vehicles. Fuel siphoned during the night may go unnoticed if trucks aren’t left empty. However, fuel management systems record rapid decreases in fuel along with the location where such incidents occur. As a result, companies can investigate fuel loss due to theft.

Pairing Fuel Management Systems with Last-Mile Software

Fuel efficiency is a concern throughout the entire shipping journey. However, last-mile delivery accounts for 53% of all delivery costs, making the final leg of the shipping journey more of a concern. Without careful planning, last-mile delivery can have a major impact on fuel consumption. The recent surge in gas prices highlights the effects of the complexity of last-mile delivery. Poorly planned routes, space between deliveries, and failed delivery attempts increase fuel consumption.

Fuel management systems offer insight into many ways fuel consumption can be successfully reduced. However, last-mile factors are unique in many ways. Modern technology can help with these issues as well. When you combine fuel management systems with last-mile delivery software, you get a powerhouse match that tackles all the issues related to fuel loss during the final stretch of the shipping journey.

Telematics in fuel management address issues like extra idling and downtime in urban areas and driver behavior. At the same time, last-mile software provides insight into the ways logistics affect fuel use during last-mile delivery.

Last-mile delivery software provides these services to improve fuel efficiency:

- Route Optimization: By putting as many deliveries on as few trucks as possible, companies can save on fuel costs. The most efficient routes shave extra miles and reduce travel time to help avoid delays that can lead to failed deliveries.

- Real-Time Tracking: Tracking tools provide complete visibility into delivery bottlenecks, and allow dispatchers to reroute drivers to avoid unexpected delays.

- Customer Communication: Tracking tools and improved routing work to increase customer satisfaction. While tracking increases visibility for fleet managers and dispatchers, it can also be used to inform customers. Accurate ETAs and delay notifications increase the likelihood customers will be available to receive shipments, reducing failed deliveries.

When the two systems are used together, fleet managers have complete insight into the most common reasons for increased fuel consumption. Both systems collect precise data to influence planning for optimal fuel efficiency.

Using Technology to Avoid Fuel Waste

Manual fuel management efforts fail to offer precise data and provide essential visibility into the challenges that affect fuel efficiency. By using modern technology, you can gain insight into fuel consumption and the factors that inflate fuel use. Modern fuel management systems are increasingly becoming a component of fleet management. When you combine the technology with last-mile delivery software, you can fully address the causes of poor fuel efficiency. Schedule a demo to learn about how Elite EXTRA’s last-mile delivery software can be integrated with fuel management software to optimize fuel efficiency.

Sources

https://www.retaildive.com/press-release/20220725-survey-62-of-shoppers-expect-their-free-shipping-orders-to-arrive-in-3-bu/

https://www.bts.gov/data-spotlight/record-breaking-increases-motor-fuel-prices-2022

https://www.automotive-fleet.com/347989/how-driver-behavior-impacts-fuel-consumption

https://www.businessinsider.com/fuel-theft-rising-gas-price-per-gallon-2022-6