The rapid growth in industrialization has resulted in a high supply of products on the manufacturer’s side. However, the demand for these products varies with time. There are periods when the demand is so high that suppliers find it hard to store the products in the warehouse. At the same time, there are periods when demand is relatively low such that suppliers have to store their products in a warehouse for longer durations. To overcome this problem, more and more businesses are adopting Just in Time Delivery.

This post will walk you through everything you need to know about Just in Time (JIT) Delivery, including what it is, why companies use it, and who can benefit from it.

What is JIT Delivery?

Order delivery speed is an increasingly examined supply management aspect, especially given the rising consumer demands for same and next-day delivery. Just-in-Time Delivery refers to an inventory and supply chain management approach which aims to increase efficiency by reducing inventory. It basically entails producing and delivering products to customers on demand instead of maintaining a large inventory of items that may not be sold or used immediately.

JIT delivery requires moving inventory for delivery primarily on an “as-needed basis” to significantly reduce inventory carrying costs by ensuring that inventory flows from the moment it’s picked. It aims to ensure that a minimal inventory can satisfy the existing consumer demand and delivery can take place immediately so that customers can get the exact product they want whenever they need it.

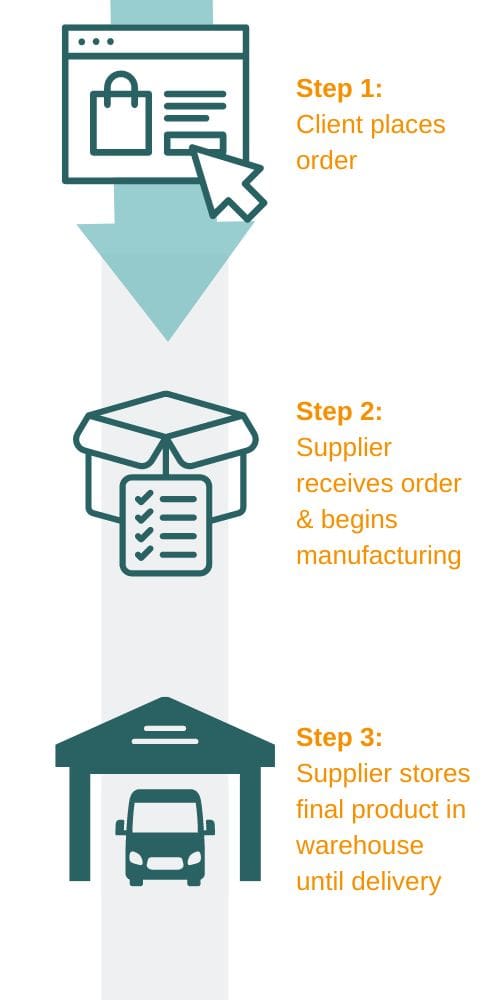

Here’s a breakdown of how JIT delivery works:

- The client places an order for a given product

- The supplier receives the order and begins manufacturing the product to fit the customer’s specifications

- The supplier then transports the final product to a storage facility or warehouse, from where the logistics services company delivers it to the customer. The logistics services company is required to deliver the product to the customer just in time so that the customer can use it as soon as possible.

Companies can implement JIT delivery to decrease waste and increase efficiency by receiving goods only as needed for production, which cuts inventory costs. Producers need to forecast demand accurately for this inventory management strategy to be successful.

Characteristics of JIT Delivery

Packaging and supply chain operations don’t store products in an in-house warehouse; the products are only received when they’re ready to be implemented into outgoing orders. As such, JIT delivery enables supply chain management companies to cut inventory costs and create more usable space in their warehouses for items that are ordered more variably.

However, whereas ‘just in time delivery’ allows supply chain companies to cut costs for inventory management and storage, it makes it challenging for these companies to forecast demand accurately.

An organization’s JIT delivery services must have the following attributes to achieve maximum responsiveness

- Zero inventory

- A continuous flow of production

- Perfect quality—defect-free production

- Producing as needed.

How JIT Impacts Delivery and the Overall Supply Chain

Proper supply chain management is crucial for any logistics operation, and JIT delivery is no different. While keeping the supply chain moving seamlessly without any bottlenecks is vital for all forms of delivery, with just-in-time delivery, it is even more significant. This is because with JIT, the products need not only be kept moving, but they also need to arrive at a specific location at a precise time. This way, there won’t be a need for additional storage costs, nor will there be any unforeseen waiting.

Finding a delicate balance in the supply chain is essential to ensuring that just-in-time delivery works properly. A successful supply chain management process means that storage costs, inventory costs, and inventory costs are well-managed such that there aren’t any holdups or excess inventory.

Another way JIT affects the supply chain is by making forecasting challenging. All manufacturers, including those who don’t use JIT, must predict their future needs. They create models, crunch the numbers, and attempt to determine what their future needs will be in terms of materials.

That said, while demand forecasting will always be secondary to consumer needs, it’s an essential aspect of the supply chain. Consumers value quick response times and flexibility in their JIT delivery services. This means that manufacturers and vendors should be able and willing to fulfill last-minute changes to customer orders and still deliver the products ordered on time.

The goal of any supply chain is to deliver to customers the products they want when they need them, all while spending as little money as possible. Just-in-time delivery can help ensure that just that is achieved.

Who Can Benefit from JIT Delivery

Although JIT was pioneered for the auto industry, its benefits extend to a wide range of industries. Here’s a look at some of the industries that can benefit from JIT delivery:

- Apparel: Companies in the apparel industry can leverage JIT delivery to enhance their production. One company in the apparel industry that has made the most of JIT is Nike. It used this inventory management system to improve its disconnected production plants across Southeast Asia. After implementing the JIT delivery system, Nike realized an increase in its production by 20% and a reduction in lead time by 40%. Moreover, it introduced new models to the market 30% faster.

- Automotive: Generally, the concept of just-in-time was initially meant for the automotive industry, and many companies in the industry are using it to increase their productivity. One such company is Toyota. At Toyota, only when orders are received from customers and a car is ready to be built does the company receive raw materials on its production floor. As such, the company cuts its cost by only holding the inventory it needs at a given moment.

- Technology: The technology industry can benefit from JIT delivery in a number of ways, including reducing the cost of holding inventory and enjoying the advantages of lean operations. For instance, Dell benefits from JIT by running a lean operation. Rather than stocking its pre-assembled computers in a warehouse, it sells directly to consumers. This way, it cuts its costs and lead time.

- Restaurant: The restaurant industry is a great example of the implementation of JIT. In this industry, a JIT system will only shift inventory when a customer makes an order and not before. When a customer places an order, that order is prepared, cooked, packaged, and then delivered to them. JIT gets the job done by ensuring that everything moves smoothly so that minimum inventory satisfies the existing demand. As such, it ensures not only the freshness of food but also that restaurants only use the inventory and resources they need.The Burger king franchise is an example of a business in the hospitality industry using JIT delivery. Even though they keep stock of all the ingredients they need, food is only prepared when a customer makes an order. By doing so, they keep food fresh and minimize waste.

- Retail: Just-in-time delivery can help businesses in the retail industry align their sales and production to maximize profits. Zara, a retail business, enjoys the benefits of JIT delivery to align its sales and production geographically, thereby ensuring that each of its stores only receives the inventory it needs. This inventory management system allows Zara to respond quickly to the fashion market changes.

- Publishing: JIT delivery system is popular among self-publishing businesses and independent publishers, and for a good reason. It allows them to print and assemble books as needed, reducing costs due to unsold inventory.

Regardless of the industry, if you’re holding inventory on-site, implementing JIT delivery can help cut your storage costs and streamline your operations.

Is JIT Delivery Right for Your Business?

Before implementing the JIT delivery system, you should assess if your organization is ready for it. Some of the factors that you should look into include the following:

- Turnarounds: Ask yourself if your products can be manufactured or supplied quickly. Suppose it takes a long time to manufacture or supply your product; JIT delivery may not be suitable for your business. This is because one of the building blocks of this inventory management system is that customers receive the product they want when they want it.

- Flexibility: You should have enough flexibility in your manufacturing and supply chain to adapt to various disruptions, including natural disasters and supplier disruptions. You don’t want to disappoint your customers after they have placed an order.

- Forecasting: You should determine whether you have enough confidence in your sales predictions to accurately depict a decline in consumer demand, including seasonality.

- Workforce: Your ability to successfully implement JIT delivery also depends on your employees. Successfully implementing a just-in-time delivery system requires complete support and understanding from everyone in your organization, especially your employees. Just-in-time delivery requires that your employees undertake specific duties and be flexible such that team members can fill in when and where needed in the production process. Therefore, you need to ask yourself whether your employees are up to the task before implementing a JIT delivery system.

- Technology: Ask yourself whether your existing inventory software management supports JIT delivery. If not, are you able to acquire one that does?

- Vendors: For a JIT delivery system to be effective, you need to have reliable suppliers capable of delivering the required products on time, every time. You also need an efficient order fulfillment system to get orders through on time.

What are the Pros and Cons of JIT Delivery

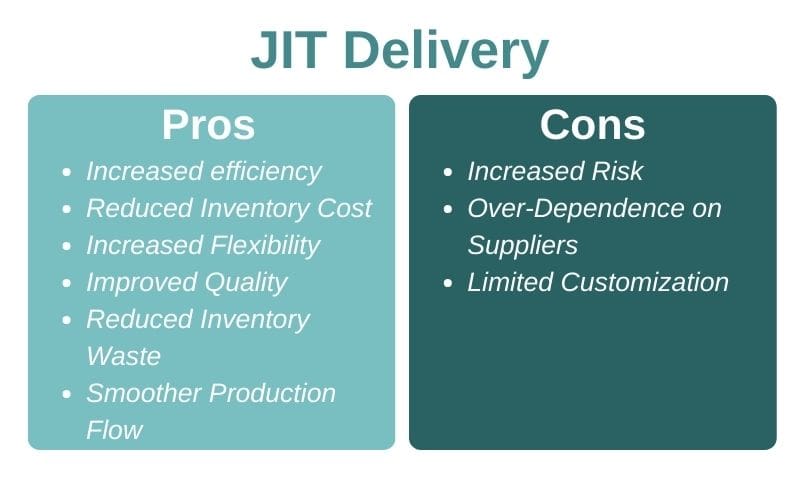

The concept of JIT delivery comes with a number of pros and cons.

Pros of JIT Delivery

- Increased Efficiency: Just-in-time delivery can help manufacturers reduce lead times since they don’t need to order products and materials in advance. This can enable them to respond to changes in customer demand more quickly and minimize the risks of short production runs.

- Reduced Inventory Cost: By only receiving the products and materials whenever they need them, manufacturers can cut the quantity of inventory they need to store, which reduces warehouse storage costs, inventory control, and insurance. It also increases the availability of storage space in the warehouse.

- Increased Flexibility: Just-in-time delivery enables manufacturers to adjust their production process in response to changes in market conditions and customer demand.

- Improved Quality: JIT delivery services eliminate the need to store large volumes of inventory, thereby helping manufacturers reduce the risk of using outdated or defective products in the production process.

- Reduces Inventory Waste: JIT delivery eliminates overproduction, which often occurs when the supply of a given product exceeds its demand, accumulating unusable stock. The unusable products turn into dead stock, which consumes warehouse space and increases waste.

- Smoother Production Flow: Just-in-time delivery services help eliminate the challenges and delays that often occur throughout the production process. It shortens production cycles, ensures more functional production cells, shortens production runs, and reduces product defects.

Cons of JIT Delivery

Whereas JIT delivery offers great benefits to businesses, it also has some downsides, especially if not implemented properly. Here’s a look at some of them:

- Increased Risk: When implementing JIT delivery, you won’t have a buffer inventory to fall back on in case of production delays and other unforeseen scenarios. This can increase the risk of lost sales and production disruptions.

- Over-Dependence on Suppliers: Just-in-time delivery relies on the timely delivery of products and materials from suppliers. Suppose your supplier fails to honor their delivery commitments; your production process can be disrupted, causing delays.

- Limited Customization: Generally, JIT delivery is ideal for manufacturers who produce standardized products in large volumes. Manufacturers offering a wide range of customized products may find it more challenging to implement JIT delivery.

Wrapping Up

In the current dynamic and hyper-competitive business environment, you need a strategy that gives you a competitive edge. Just-in-time delivery is an excellent option for cutting down storage costs, improving productivity, and delivering products with better efficiency. It also enables your business to establish a good customer-supplier relationship.

Need help implementing JIT delivery? Elite EXTRA can help. The Elite EXTRA software suite has solutions that can improve your logistics operations, impress your customers, and enhance your bottom line. Contact us today to learn more about our solutions.

Sources

https://www.forbes.com/2005/12/08/zero-inventory-crossdock-cx_rm_1208zero.html?sh=bd5684724719

https://www.shopify.com/blog/what-is-dead-stock